Advantage:

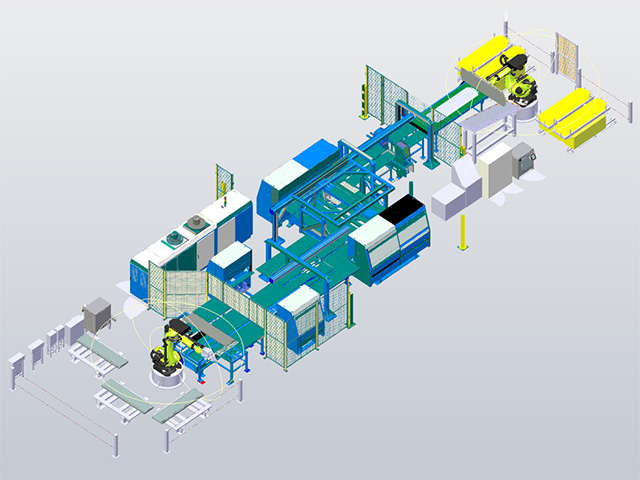

①The feeding robot can grasp one type of plates, or alternatively grasp two different types of plates, and automatically detect the types to realize mixed material production, so as to solve the pain point that the left and right parts of the door panel can not be produced in a complete set of automation.

②At the blanking end, two robots weld different positions at the same time to improve the beat and production efficiency. The beat of the whole line is 23S / piece.

③AGVs can automatically connect the plate silo at the feeding end and the spraying line at the blanking end.