One stop service of production equipment

Your current location:Home / Case / One stop service of production equipment />

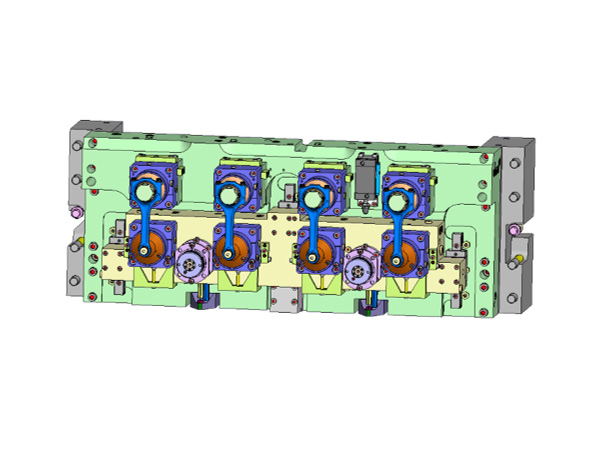

In this project, the rough and fine processing equipment of connecting rod is reformed (Software + hardware), the production of two new connecting rod varieties is integrated, and the unstable size is optimized and improved according to the existing production situation to improve the production quality and stability.